Sheave type main size steel wire ropeΦΦMM bearing type weight KG ΦD ΦD1 ΦD2 R B HL3151 315 350 40 65 60 812 6208 12 HL3152 50 64 6210 13 HL3153 360 60 8 68 1214 6212 14 HL3154 70 72 6214 16 HL4001 400 450 60 8 68 1214 6212 21 HL4002 70 72 6214 23 HL4003 460 80 10 76 1418 6216 28 HL4004 120 104 42224 44 HL5001 500 550. Our wire rope sheaves are made from quality materials and machined to precise dimensions and tolerances in order to meet our high standards.

Wire Rope Sheave Type Sr Certex Denmark

Consult Safe Working Limits of Wire Rope or wire rope manufacturers recommendations.

. Sheave and Drum Diameters. In stock and ready to ship. Sheave design for wire rope For more assistance you can also consider strategies and guides in other on the web meansTokyo Samurai is likewise a good choice even though it wants a membership from you.

Wire rope and sheave life through changes to the sheaves and addresses the superintendent who says they dont make ropes like they used to and Ive never EVER had to regroove a sheave Rope Performance Groove Types The U-groove Sheave The U-groove sheave found predominantly in older installations is the sheave of choice for. My favorites Marks handbook as well as machinerys handbook aren. Any reference that will help me determine appropriate geometries for the given ropes that I am using.

Sheave design guidelines for rope. Sheave and drum design factors affecting life performance of a wire rope are as under. For normal applications use 35 to 45 opening.

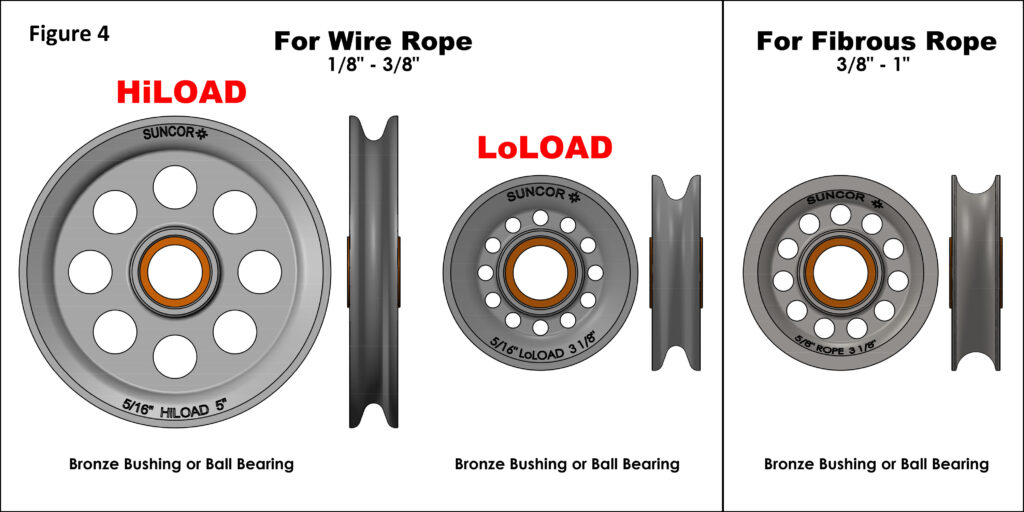

Aluminum Nylon Custom More. Cast nylon sheaves are superior to aluminum or steel sheaves for wire rope load applications. Check Out E-Rigging Reviews To See How Customers Are Happy With Our Service And Products.

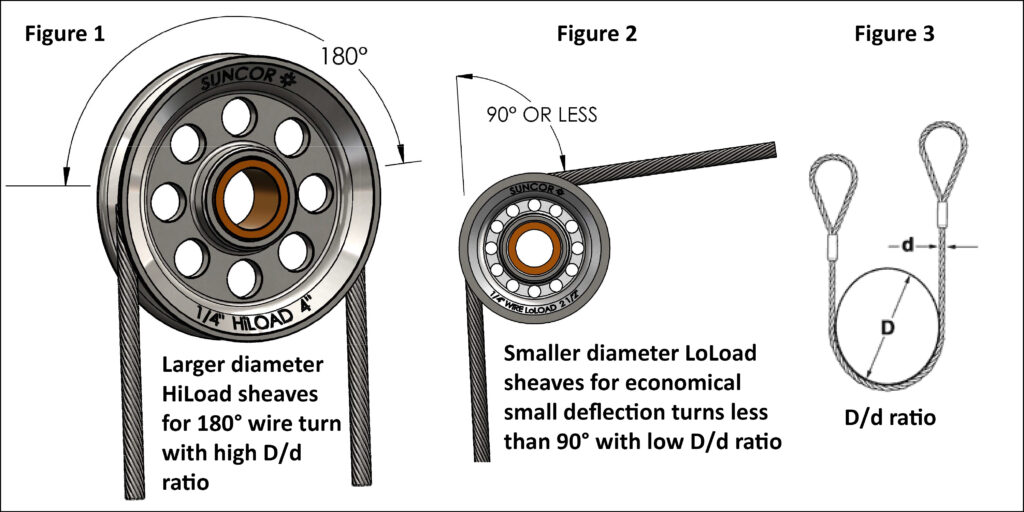

A properly sized sheave groove radius should measure 053 to 054 times the nominal rope diameter or in other words the groove diameter should be 6 to 8 larger than the nominal wire rope diameter. The severity of these stresses are directly related to the rope load and the Dd ratio or the ratio of the tread diameter of the sheave or drum D to the diam-eter of the rope d. That means that for example a 23 mm nominal wire rope requires the sheave groove diameter to be between 2438 mm to 2484 mm radius of 122 mm to 124 mm.

C-r-Ilncluded in shcave design is thc material rom which the sheave is made and its heat treatment if the material is metaL Also affecling sheave life is wire rope design espccially wirc size and hard. Sheave and Drum Design. Hardhat Sheaves TM - Custom Cast Nylon Sheaves.

Sheave Design For Wire Rope. Just in case you are a little low about the funds check out considering the livejournal group J Journal Scans. Ad Finish Your Project With Rigging Hardware Including Cable Rope Chain Fittings More.

15 x d or d x 2. I am looking for a resource for sheave design guidelines. They provide exceptional durability and performance in demanding applications and significantly improves wire rope life.

Materials heat treatment head fittings bedset sheaves proof load examination marking. When sheaves for your wire rope are too large or too small there is. A groove angle throat angle of between 30.

Be sure to use an adequate size wire rope. Choose from our selection of wire rope sheaves including pulleys for wire rope mounted pulleys for wire rope and more. Tips on Designing the Right Steel Cable Sheaves for Your Wire Rope Pay attention to sheave groove size and diameter.

Since the wire. Stampyoldani Mechanical OP 4 Aug 08 1533. Timt opcrates over sheaves design of lhc sheavc has a s ignif calll ef-Ject on the service life of the wire rope.

For rope wrap angle of 180 For rope wrap angle of 90 Groove Tmax 2000rDt Tmax 2828rDt Bore Tmax 2000BLTB Tmax 2828BLTB Note. The groove diameter of a cast nylon sheave should exceed the wire rope diameter by about 5. Sheaves drums and rollers must be of a correct design if optimum service is to be obtained from both the equipment and the wire rope.

Minimum 053 to 0535 x d Maximum 055 x d Recommended. This allows for the tolerance in the rope diameter and assures good support for the wire rope. Design based on minimum breaking load or round strand equal lay 6 x 24 to 6 x 41 wire rope with independent wire rope core.

Read customer reviews find best sellers. Sheave and Drum Diameter All wire ropes operating over sheaves and drums are subjected to bending stresses which eventu-ally cause the wire rope to fatigue. Rope breaking strength is determined in a standard test wherein fittings are attached to the ends.

Sheave design guidelines for rope. For a sheave ratio greater than 181 calculate only bore pressure. Ensure sheave groove hardness.

Ad Browse discover thousands of brands. Sheave diameter not less than 15 times rope diameter. January 30 1970 - BSI.

The following are recommended values. We recommend only sheaves made of steel or cast steel. The hardness of sheaves is a factor that is often overlooked.

The groove depth should be at least 15 times the rope diameter to prevent jumping. We have the capability to manufacture your wire rope sheaves to your design and specifications or you can choose your wire rope sheave from our large inventory of wire rope sheaves. In addition we offer many other options to.

Ad 4 to 48 Dia Sheaves. For roller bearing sheaves note Mechanical Advantage of 106 W P X M 10 X 106 106 tons 3. Sheave Design is Critical to Wire Rope Service Life Bending Wire Rope over Sheaves and Drums.

With Bearings 180 Wrap Angle 90 Wrap Angle. 1 over the actual wire rope diameter.

Why Sheave Design Is Critical To Wire Rope Service Life

Sheaves And Drums Python Wire Rope

Mariners Repository Lifting Equipment Sheaves Blocks Drums With Significance To Fleet Angle

Stainless Steel Sheaves Selection And Use Suncor Stainless

Stainless Steel Sheaves Selection And Use Suncor Stainless

0 comments

Post a Comment